Option B and E seem right to me. From what I remember, the SCO work area is built for creating supply requests and letting you drill into execution docs (like PO or transfer orders). The changing or releasing side is more for downstream apps. Pretty sure but if anyone's seen C in the actual SCO UI, let me know.

Is the question specifically asking for all possible roles, or only the primary function as configured in the task? That would affect whether billing and payable invoices are in scope.

Pretty sure it's A, C, D. Order Capturing (B) is a common decoy here. SCO core focuses on orchestration logic, decomposition of tasks, and integrating with business services-not capturing the original order itself. Seen similar verbiage in Oracle training so I'm confident, but correct me if you think otherwise.

C or D depending on what exactly the question means by "functional". If they're asking for core modules only, then A, C, D make sense, but if "Order Capturing" is included in scope (like end-to-end process), then B could be right. Is order capture considered part of orchestration here?

Maybe C. Since the frequency is weekly and you run it before the next cycle on Nov 14, I think nothing gets generated. Not totally sure though, can someone confirm?

Isn’t "Locator Transfer" (E) just a subtype under Subinventory Transfer (C) in Oracle’s screens? I think the setup needs B (Move Request) and C for full traceability, but not sure if real-life setups always require both.

Looks like it's A, since enabling that option skips the need for manual pick release. Oracle docs and practice tests mention this. Anyone using the official guide notice anything different?

Option A looks right, but does the question mean you want every line to bypass manual pick or just some of them? If 'all' lines should be auto-released, I'd go A, but if granular control is needed maybe B would fit better.

Pretty sure it’s D. Back-to-Back is described like this in the official Oracle guide and matches what I saw on sample exams.

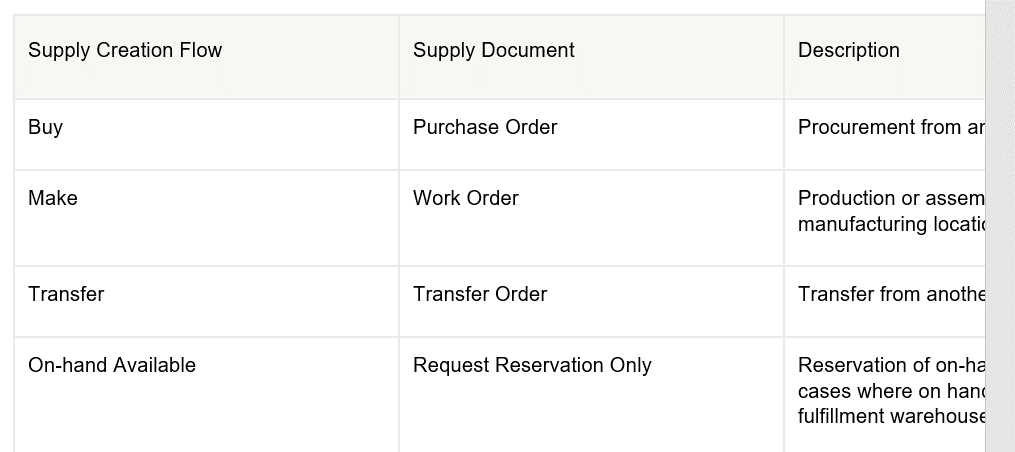

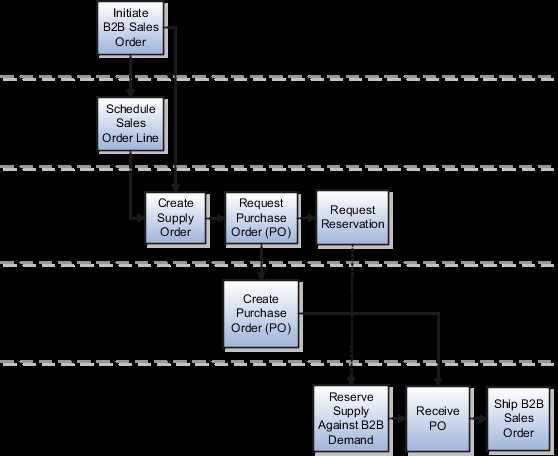

Back-to-Back Supply Creation Buy Flow

The supply document for a back-to-back buy flow is a purchase order. Based on supply

recommendations from Oracle Global Order Promising, a purchase order is created and reserved

against the sales order. When the purchase order is received by the supplier, on hand is created to

ship out the back-to-back sales order.

The following figure shows the back-to-back supply creation buy flow.

Back-to-Back Supply Creation Buy Flow

The supply document for a back-to-back buy flow is a purchase order. Based on supply

recommendations from Oracle Global Order Promising, a purchase order is created and reserved

against the sales order. When the purchase order is received by the supplier, on hand is created to

ship out the back-to-back sales order.

The following figure shows the back-to-back supply creation buy flow.

Pretty sure this matches what I've seen in actual exam questions: after the sales order is scheduled, the system generates a purchase requisition first if there's no inventory. The answer "See the" fits the step-by-step logic here, though not 100% obvious from wording. Others agree?

Yeah, seen a similar question in practice sets. The flow starts with the sales order and then creates a purchase requisition, then a PO if no stock is found. "See the" matches that step sequence pretty well I think.

Can someone clarify if the buy flow always means a purchase order gets created, or does it depend on Oracle finding on-hand stock first? If there’s no inventory, I get that PO generation is triggered, but is there any scenario where buy flow skips that step?

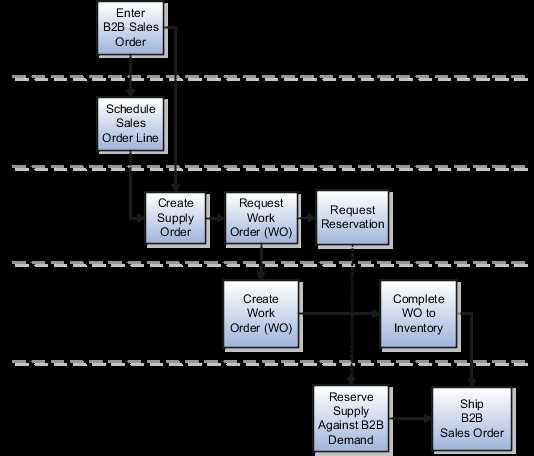

The supply document for a back-to-back make flow is a work order. As soon as the work order is

created in Oracle Fusion Cloud Manufacturing, it's tied to the back-to-back sales order in the form of

a reservation in inventory. The work order goes through the regular production process and the work

order completion transaction issues finished goods to inventory.

Note: Back-to-back flow is currently supported for only discrete manufacturing.

The following figure shows the back-to-back supply creation make flow.

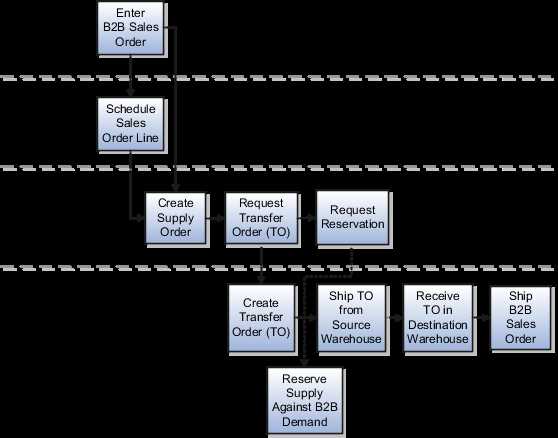

Back-to-Back Supply Creation Transfer Flow

The supply document for a back-to-back make flow is a work order. As soon as the work order is

created in Oracle Fusion Cloud Manufacturing, it's tied to the back-to-back sales order in the form of

a reservation in inventory. The work order goes through the regular production process and the work

order completion transaction issues finished goods to inventory.

Note: Back-to-back flow is currently supported for only discrete manufacturing.

The following figure shows the back-to-back supply creation make flow.

Back-to-Back Supply Creation Transfer Flow

The supply document for a back-to-back transfer flow is a transfer order. The transfer order is created

in inventory and reserved against the back-to-back sales order. When the transfer order is ready to

be fulfilled, an interorganization shipment moves goods from the source organization to the

destination organization. An interorganization receipt in the destination organization (which is also

the fulfillment warehouse on the back-to-back sales order) creates on hand to fulfill the sales order.

The following figure shows the back-to-back supply creation transfer flow.

The supply document for a back-to-back transfer flow is a transfer order. The transfer order is created

in inventory and reserved against the back-to-back sales order. When the transfer order is ready to

be fulfilled, an interorganization shipment moves goods from the source organization to the

destination organization. An interorganization receipt in the destination organization (which is also

the fulfillment warehouse on the back-to-back sales order) creates on hand to fulfill the sales order.

The following figure shows the back-to-back supply creation transfer flow.Yeah, it's work order for back-to-back make flow. That's the doc Oracle uses when the item is manufactured in-house, not just transferred. If it was a transfer between organizations, then it'd be a transfer order instead. Pretty sure that's how it's supposed to work, but open if someone has seen something else.

Hmm, I think this depends on whether they mean "make" or "transfer" flow. For back-to-back make flow, the answer is probably "work order" since that's the supply doc tied to the SO in discrete manufacturing. But if it's transfer flow, then it'd be a "transfer order". So I'd say make sure you read for which scenario they're asking!

Pretty sure that's what gets created for back-to-back, unless the process specifically requires manufacturing. If it's just moving stock between orgs, transfer order would be the system doc. Correct me if I'm missing some scenario.