Q: 11

SIMULATION

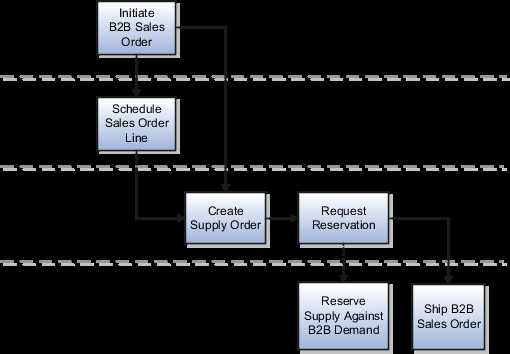

Back-to-Back Supply Creation On-Hand Flow

The back-to-back on-hand available (ATP) flow is the simplest in terms of the number of steps that

constitute the flow. This flow occurs where on hand supply is available in the fulfillment warehouse

for the ordered back-to-back item at the time of order promising. Because on-hand goods already

exist in the form of on hand, Oracle Supply Chain Orchestration directly sends a request to reserve

the on hand quantity against the back-to-back sales order. You can ship the sales order immediately

after the reservation is created.

The following figure shows the back-to-back supply creation on-hand flow.

Your Answer

Discussion

Reserve on-hand inventory

That's what triggers fulfillment in the back-to-back flow when ATP is available. Shipping comes right after, but reservation is the enabling step. Pretty sure that's what Oracle wants here.

That's what triggers fulfillment in the back-to-back flow when ATP is available. Shipping comes right after, but reservation is the enabling step. Pretty sure that's what Oracle wants here.

Is the main step here just reserving on-hand inventory, or do they want immediate shipment as the answer?

Reserve on-hand inventory. Pretty sure that's what Oracle does first when ATP finds stock available, skips all the extra steps like procurement or transfer. Some might confuse this with make-to-order but here it's just a direct reservation then ship. Let me know if you see it differently.

Does the question specify if you have to describe the process in detail or just name the key step? That would change what I write here.

Reserve on-hand inventory. This is the core step in the process based on what I've seen in the official guide and practice tests, though I guess you could argue for immediate shipment depending how the question is worded. If anyone's seen an official Oracle example that says otherwise let me know.

Makes sense, but I'd write "immediate shipment" for the main process here. Not 100 percent sure if that's what they're after.

Had something like this in a mock, it's just reserve on-hand inventory. Maybe there's a trick but this matches what I've seen.

Be respectful. No spam.